Company Introduction

Related Industries

Products

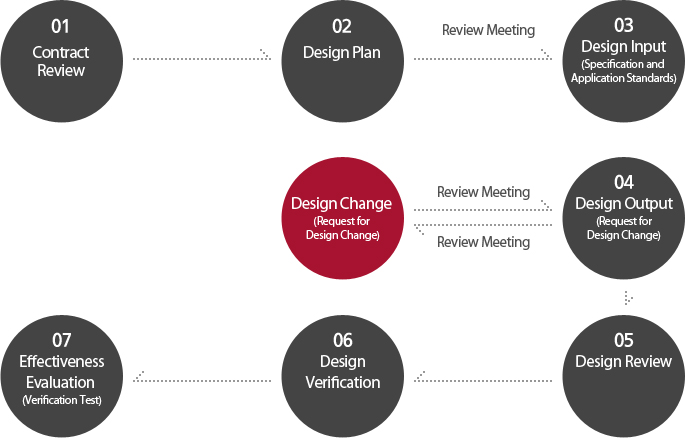

R&D

Customer Center

HOME > R&D > R&D Institute

The global excellence in quality was verified by acquiring the international quality certification and the overseas major ship

classification certification. A foothold is being established as the global valve maker satisfying the customers with the

best quality through the steady R&D investment.